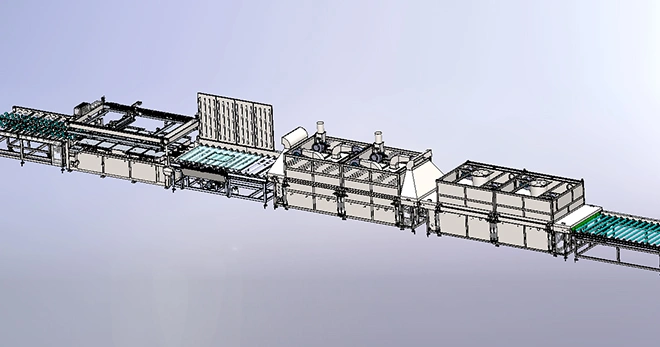

Efficient handling systems are essential for maintaining continuous flow in automated glass production lines. These glass handling units support a wide range of operations, including loading, transferring, turning, lifting, tilting, buffering, and unloading. Through integrated control logic, they ensure precise coordination between stations, helping optimize the overall process. Designed to adapt to different production layouts, our glass handling equipment contributes to safer handling, reduced breakage, and improved efficiency throughout each stage, from raw material input to final packaging.

Automatic glass loading conveyors are designed to streamline the initial stage of flat glass processing lines by transferring panels from storage racks to conveyors without manual lifting. Ideal for handling glass and other rigid flat materials, these systems improve workflow efficiency, reduce labor intensity, and support automation in large-scale production setups.

Learn MoreVertical glass accumulators are used to temporarily store glass panels during processing, helping maintain a smooth production flow across different stages of the line. They’re especially useful when working with rigid materials like glass and help save floor space by using a vertical design.

Learn MoreOur guiding conveyor features a centralized clamping system that keeps glass panels properly aligned as they move along the line. Adjustable guide plates on both sides secure the panels according to their width. These plates are coated with PTFE to prevent scratching or damage during transfer.

Learn MoreOur conveyor systems are designed to support post-print quality control. By tilting the glass panels at an ideal viewing angle, it allows operators to carry out accurate visual inspections under dedicated lighting. The structure ensures stability during movement and makes inspection tasks easier and more efficient within the production line.

Learn MoreTilting unloading conveyors are typically installed at the end of an automated line to assist with manual unloading. By tilting the glass to an ergonomic 70-degree angle, they allow operators to lift and remove panels more easily and safely. Their design helps reduce handling risks while keeping the workflow smooth and efficient.

Learn MoreRotation conveyors are used to change the orientation of glass panels during transfer, allowing for 90°, 180°, or 270° rotation depending on the production needs. These skatewheel conveyors are designed to optimize alignment between processes, improving workflow flexibility in automated glass handling lines.

Learn MoreUsed in fully automated production lines, the glass lifter is designed to transfer glass sheets between different floor levels. It supports vertical layouts by enabling seamless flow across floors, helping optimize space and improve process efficiency.

Learn MoreUsed in automated production lines, corner conveyors transport glass panels at a 90 degree angle, allowing for efficient movement in tight spaces while maintaining glass panel orientation. This function is especially useful in compact layouts where straight-line transfer isn’t feasible.

Learn MoreContact us for more information about screen printing, drying, and handling systems for glass production. Our team is ready to assist you!