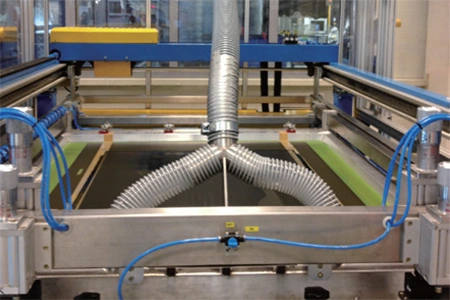

GHA Series (High Efficiency, Large Size)

This series of screen printing machines is designed specifically for automotive glass such as windshields, backlites, and sunroofs. Instead of the usual step-by-step setup, it uses a three-section structure, positioning, printing, and unloading, that works at the same time. With a high-precision shuttle system making everything run smoothly, it reaches an output of 300 to 360 pieces per hour. It can handle large formats up to 1200 × 1800 mm, making it a solid option for high-volume production of passenger car glass with consistent, high-quality results.

| Model | BWSP-1218GHA |

| Max. printing size (mm) | 1200 × 1800 |

| Min. printing size (mm) | 400 × 700 |

| Substrate thickness (mm) | 1.6 – 6 |

| Positioning adjusting range (mm) | X ±20, Y ±20, θ: 5° |

| Off-contact adjusting range (mm) | 8 – 35 |

| Peel-off distance (mm) | 0 – 45 |

| Printing accuracy (mm) | 0.08 |

| Positioning precision (mm) | ±0.1 |

| Power supply | 3N 380V 50Hz 5 kW |

| Air supply | 0.6 MPa – 0.8 MPa |

| Production capacity (pcs/hour) | Approx. 300 |

If your glass dimensions fall outside the specifications listed above, there’s no need to worry. Get in Touch and we’ll be happy to provide a tailored printing solution that suits your production needs, free of charge.