Our glass washing machines are widely used in glass production lines where cleanliness directly affects product quality, such as in automotive, architectural, and mirror manufacturing. These glass washing systems are designed to remove dust, residues, and contaminants from glass surfaces before or after printing and coating processes. Our horizontal glass washers offer easy integration into automated lines, with flexible configurations to match specific production requirements.

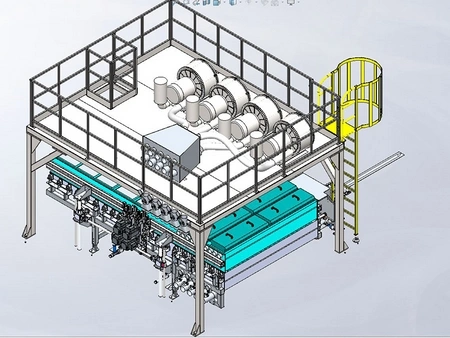

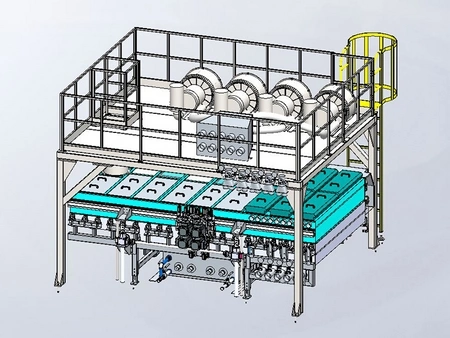

| Model | TWWM-1800A |

| Max. glass washing size (mm) | 1800 |

| Min. glass washing size (mm) | 500 × 700 |

| Glass thickness (mm) | 1.6 – 19 |

| Number of cylindrical brushes (sets) | 3 |

| Number of air knives | 3 |

| Water heating power (in Tank) | 9 kW × 3 |

| Transfer speed (m/s) | 2 – 10 |

| Power supply | 3-phase 380V 50Hz, 65 kW |

| Machine dimensions (L × W × H) (mm) | 4900 × 3600 × 1650 |

The glass washing we offer are typically used to clean and dry glass before they go through tempering. To pick the right one, it’s important to evaluate the size and thickness of the glass you'll be processing, since these factors directly impact the required configuration and working range. It's also important to match the equipment’s speed and automation level to your production goals. Beyond that, look for features that help improve the cleaning and drying process, like stable transmission, reliable heating, and consistent air knife performance. Glass washing machines that are easy to clean and maintain will help minimize downtime and reduce long-term operating costs.

Efficient glass washing machines usually offer adjustable speed control and water pressure to suit different production needs. A good water circulation system is essential for reducing water usage and improving overall efficiency. Automatic loading and unloading can boost throughput while lowering the risk of glass damage. It's also important that the unit includes proper safety features, such as protective guards to shield operators from moving parts and clearly marked emergency stop buttons. All these functions combined contribute to a smoother, safer, and more efficient cleaning process.

Contact our team to discuss printing, drying, and handling solutions tailored to your glass applications.