Architectural glass is widely used in modern buildings for both structural and decorative purposes. It’s found in façades, staircases, flooring, rooftops, and other applications where durability and design are equally important. To support these applications, we offer screen printing machines designed for flat glass with high rigidity, ensuring precise and consistent results. Whether the project requires single-color or multi-color applications, our glass printing equipment is compatible with most common architectural glass sizes available on the market. For projects involving panels larger than the standard 2500×5100 mm, we also offer fully customized glass printing solutions to meet your production requirements.

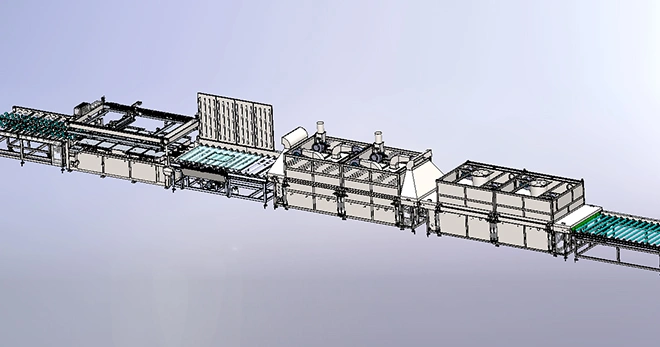

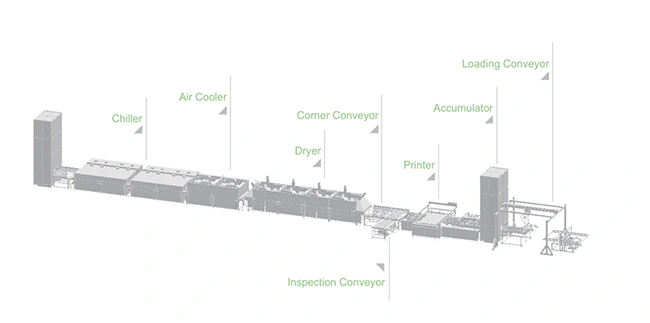

We provide complete glass printing and drying lines tailored to various types of flat and curved glass, including automotive, architectural, household appliance, and photovoltaic applications. Each solution is customized based on glass size, production capacity, and process requirements.

View MoreOur glass washing machines are widely used in glass production lines where cleanliness directly affects product quality, such as in automotive, architectural, and mirror manufacturing. These glass washing systems are designed to remove dust, residues, and contaminants from glass surfaces before or after printing and coating processes.

View MoreEfficient handling systems are essential for maintaining continuous flow in automated glass production lines. These glass handling units support a wide range of operations, including loading, transferring, turning, lifting, tilting, buffering, and unloading. Through integrated control logic, they ensure precise coordination between stations, helping optimize the overall process.

View MoreOur screen printing machines are suitable for flat architectural glass made from hard, rigid materials. This includes glass curtain walls, skylight panels, glass staircases, and flooring glass panels.

Not at all. For outdoor applications, ceramic inks are typically used. After printing, the glass undergoes a tempering process at temperatures above 650°C, which ensures color stability, weather resistance, and protection against aging, acids, and alkalis. The result is a long-lasting finish that won’t fade with time.

The standard printing range supports glass panels up to 2500×5100 mm, with a minimum printable size of 500×700 mm. If your project requires larger formats, custom-built solutions can be developed to accommodate your specific size requirements.

Contact us for more information about screen printing, drying, and handling systems for glass production. Our team is ready to assist you!