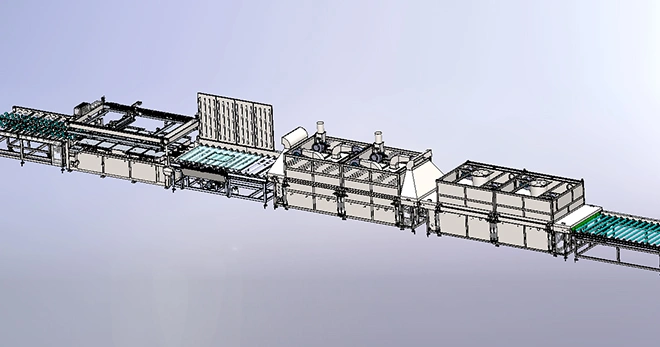

Glass printing requires reliable drying and cooling systems to ensure production efficiency and high-quality results. We offer different types of equipment tailored for various types of inks and applications, including IR dryers, UV dryers, and cooling machines.

IR dryers are used as part of complete glass printing lines to dry glass after ink application. They include heating section, conveyor system, hot air circulation, exhaust unit, and digital controls. This setup ensures even drying and helps get the glass ready for the next production step.

Learn MoreOur UV dryers can be configured with focused or parallel reflectors, depending on the surface requirements, to improve curing efficiency. Depending on the type of ink used, they can be equipped with high-pressure mercury or gallium UV lamps. The lamp and power setup is optimized to ensure efficient curing while keeping energy consumption under control.

Learn MoreAir coolers are used in glass printing production lines to cool glass panels after the drying stage. By using powerful air showers from both the top and bottom, these systems help lower the temperature of the glass quickly while supporting the final stages of ink drying. They offer various configurations to accommodate different glass sizes and production needs, ensuring efficient cooling and clean results.

Learn MoreVertical multi-layer dryers are designed for efficient drying of glass panels while optimizing floor space. By using a vertical storage and transfer mechanism, they support continuous production in a compact layout, making them ideal for high-volume printing lines.

Learn MoreChiller coolers can significantly reduce the temperature of glass panels after drying, helping stabilize inks and coatings before further processing. These cooling systems rely on an external chiller or a water source below 10°C to deliver efficient and consistent cooling performance.

Learn MoreGlass printing lines typically use IR dryers, UV dryers, air-cooling units, and cold air blowers. Each option fits a specific process depending on the type of ink and the drying or cooling needs.

IR dryers are used when printing with infrared-curable inks, offering consistent heat and even drying. UV dryers are more common for UV inks, especially when fast drying is needed without significantly heating the glass, ideal for saving both time and space.

3.Cooling machines help bring down the glass temperature quickly after drying. This prevents warping, speeds up handling, and keeps the production flow moving smoothly into the next stage.

Contact us for more information about screen printing, drying, and handling systems for glass production. Our team is ready to assist you!