GHA Series

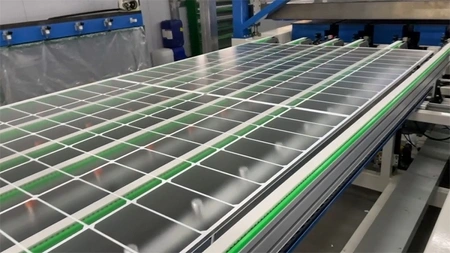

Printing on solar glass panels requires a combination of precision, stability, and the ability to handle large panel sizes. Since the process involves repeated printing cycles and fine alignment, it's important to use equipment that can keep up with the pace of production without losing accuracy.

To meet the specific challenges of solar glass printing, our screen printing machines are built with a structure optimized for both precision and efficiency. They adopt a short-edge leading feeding method, allowing larger panels (up to 1400 × 2600 mm) to move through the process more efficiently and stably. Positioning, printing, and unloading happen in parallel rather than one step at a time, which speeds up the workflow and reduces idle time. A high-precision shuttle system keeps each panel moving smoothly and accurately between stages, supporting a stable output of 300 to 350 pieces per hour. Every part of the system is designed to support high-volume production while maintaining clean, consistent print quality from start to finish.

| Model | BWSP-1426GHA |

| Max. glass panel size (mm) | 1400 × 2600 |

| Min. glass panel size (mm) | 600 × 600 |

| Glass thickness (mm) | 1.6 – 4.0 |

| Worktable flatness (mm) | 0.1 / 1000 |

| Repeat positioning accuracy | ±0.1 |

| Production capacity (Panels/hour) | 300–350 |

| Machine Dimensions (L×W×H) (mm) | 10840 × 2200 × 1650 |

- Servo-driven systems manage glass positioning, transport, off-contact distance (screen-to-worktable worktable), and peel-off motion (screen lifting from the glass), which enables accurate and consistent digital adjustments throughout the printing cycle.

- A specially designed screen frame pull-out system makes it easier and safer to install or clean the screen frame, helping reduce downtime while improving operational safety.

- The printing table features a patented low-friction composite panel that protects the glass surface from scratches and offers strong resistance to solvent exposure.

- Glass is transferred between stations using a servo-controlled shuttle guided by high-precision linear rails. A vacuum system ensures stable and accurate movement, supporting fast and smooth production flow.