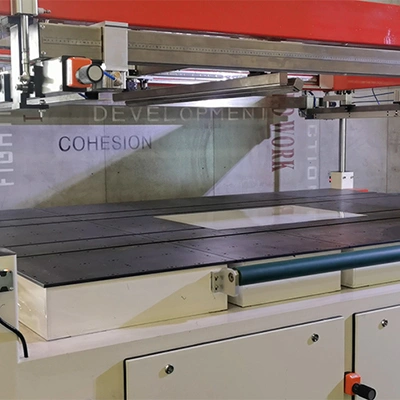

VHA Series (High Efficiency)

Small-sized glass panels used in home appliances require precise, fast, and consistent screen printing to ensure visual clarity and performance. To meet these demands, our automatic screen printing solution integrates three separate operations: positioning, printing, and unloading, into a parallel process. By eliminating traditional step-by-step sequences and adopting a shuttle-based transport mechanism, it achieves smooth coordination across all stations. This approach boosts efficiency to 550–650 pieces per hour while handling panels as small as 150 × 250 mm, covering the full range of production needs in this field.

| Model | BWSP-6070VHA-R |

| Max. printing size (mm) | 600 × 700 |

| Min. printing size (mm) | 150 × 250 |

| Substrate thickness (mm) | 3–5 |

| Off-contact adjustment range (mm) | 6–25 |

| Peel-off distance (mm) | 0–20 |

| Repeat positioning accuracy (mm) | ±0.15 |

| Glass feeding direction | SEL (short edge leading) |

| Printing accuracy (mm) | ±0.20 |

| Power supply | 3N, 380V, 50Hz, 4.5 kW |

| Machine dimensions (L × W × H) (mm) | 3500 × 1300 × 1930 |

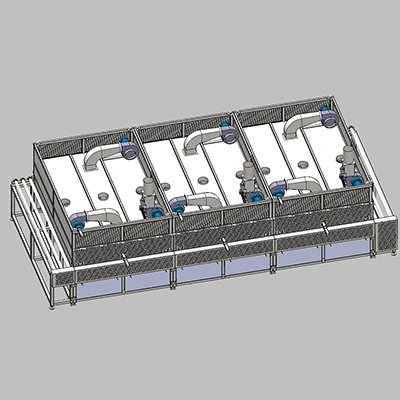

Suitable for screen printing on small-sized glass panels used in appliances such as refrigerators, freezers, stovetops, range hoods, air conditioners, washing machines, microwave ovens, and dishwashers.

- Cross-style dual-servo vertical layout enables precise centering and alignment for various glass panel sizes.

- Our proprietary composite panel is designed with a low-friction surface that prevents scratches and offers excellent resistance to solvents.

- A precision servo system combined with high-accuracy linear guide rails and a vacuum adsorption setup guarantees smooth and efficient glass transfer while maintaining consistent positioning accuracy.