Glass used in home appliances, such as refrigerator doors, oven panels, or microwave fronts, requires both decorative patterns and functional markings. To meet these specific demands, we offer screen printing equipment capable of handling single-color and multi-color jobs with precision. The production process supports continuous operation while maintaining high alignment accuracy, making it suitable for companies that prioritize efficiency and clean visuals in every batch.

Ideal for use in glass panels for refrigerators, freezers, microwave ovens, ovens, and gas stoves, these printing solutions are trusted by manufacturers looking to enhance the aesthetics and functionality of their products.

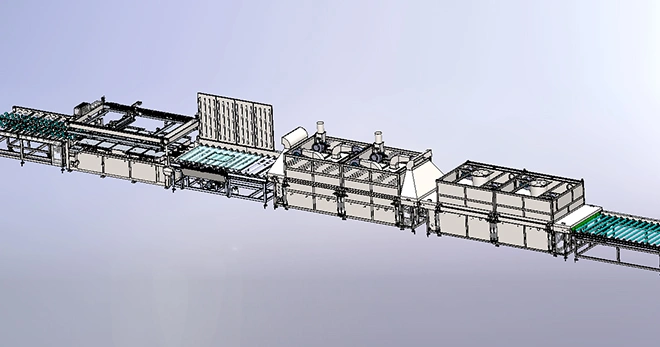

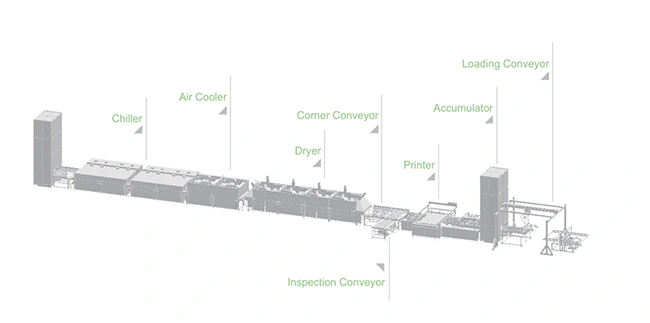

We provide complete glass printing and drying lines tailored to various types of flat and curved glass, including automotive, architectural, household appliance, and photovoltaic applications. Each solution is customized based on glass size, production capacity, and process requirements.

View MoreOur glass washing machines are widely used in glass production lines where cleanliness directly affects product quality, such as in automotive, architectural, and mirror manufacturing. These glass washing systems are designed to remove dust, residues, and contaminants from glass surfaces before or after printing and coating processes.

View MoreEfficient handling systems are essential for maintaining continuous flow in automated glass production lines. These glass handling units support a wide range of operations, including loading, transferring, turning, lifting, tilting, buffering, and unloading. Through integrated control logic, they ensure precise coordination between stations, helping optimize the overall process.

View MoreContact us for more information about screen printing, drying, and handling systems for glass production. Our team is ready to assist you!