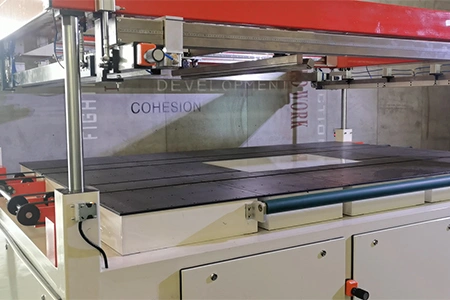

GA Series (Fully Automatic)

Architectural glass often requires precise, large-size printing processes, especially for applications like facades, partitions, or shower enclosures. This screen printing machine series offers a well-rounded solution by integrating with a complete production line, handling everything from automatic glass loading and alignment to printing, drying, air cooling, and unloading. It’s not only suitable for architectural glass applications, but also for printing large automotive panels such as front and rear windshields on buses. Supporting diverse production needs within a single setup helps reduce equipment investment costs, while customizable configurations are available for specific layouts, automation levels, or oversized glass formats beyond the standard.

| Model | | | | |

| Max. printing size (mm) | 2000 × 3000 | 2440 × 3660 | 2440 × 4500 | 2500 × 5100 |

| Min. printing size (mm) | 500 × 700 | 600 × 800 | 700 × 900 | 700 × 900 |

| Glass thickness (mm) | 3–19 | 3–19 | 3–19 | 3–19 |

| Power supply | 3N 380V/50Hz 5.5kW | 3N 380V/50Hz 6.5kW | 3N 380V/50Hz 6.5kW | 3N 380V/50Hz 6.5kW |

| Outer dimensions (L×W×H) (mm) | 4500 × 3000 × 1850 | 5200 × 3600 × 1850 | 6000 × 3600 × 1850 | 6600 × 3600 × 1850 |

| Production capacity (pcs/hour) | Approx. 160 | Approx. 150 | Approx. 130 | Approx. 120 |

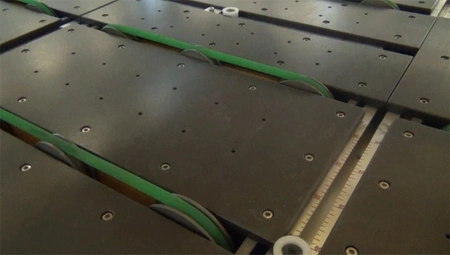

- The printing table features a patented composite surface that helps prevent scratches on the glass during operation. Its low-friction material also provides strong resistance to solvents commonly used in screen printing.

- To further reduce the risk of damage, the worktable includes an air floating system that lifts the glass slightly during transport and alignment. This setup supports various panel thicknesses, from 3 mm up to 19 mm, ensuring stable handling and accurate printing.