IR dryers are used as part of complete glass printing lines to dry glass after ink application. They include heating section, conveyor system, hot air circulation, exhaust unit, and digital controls. This setup ensures even drying and helps get the glass ready for the next production step.

Offers smooth and stable transport, especially suitable for small glass panels. The equipment is more affordable, but the Teflon mesh belt requires regular replacement, typically once a year.

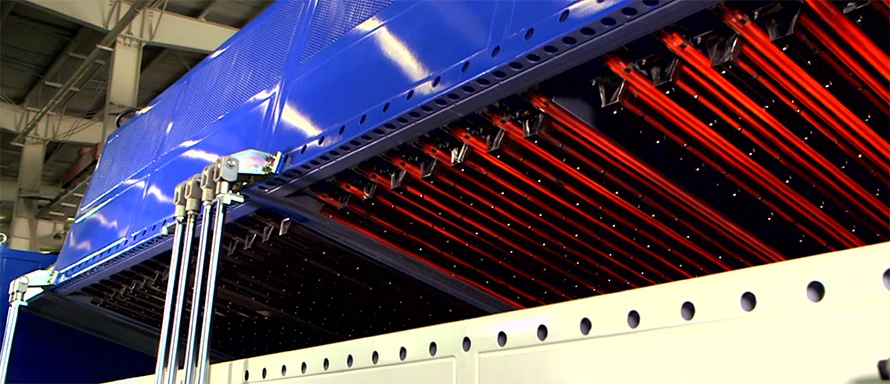

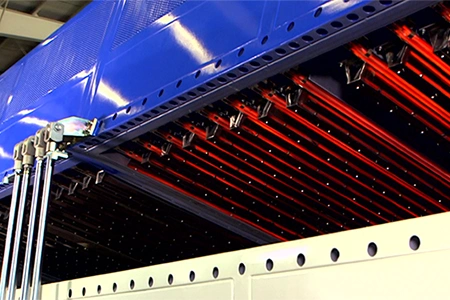

Requires minimal maintenance. Once heated, the rollers help raise the glass temperature, enhancing the drying efficiency. Although the initial cost is higher than mesh belt systems, there’s no need for future replacement.

Also low maintenance and less likely to scratch glass surfaces. Like metal rollers, they don't require regular replacement, but care must be taken, ceramic rollers are more fragile under vertical force due to their material characteristics.

Contact our team to discuss printing, drying, and handling solutions tailored to your glass applications.