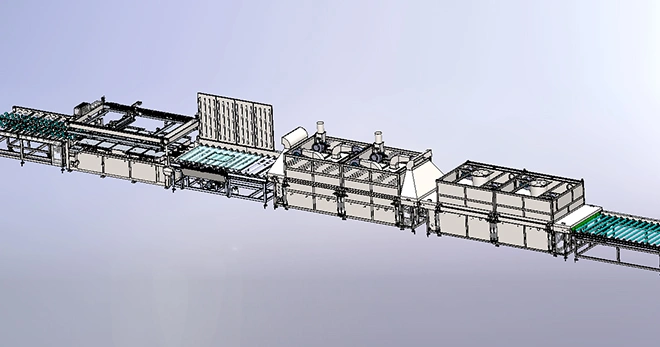

Roller coating machines for glass are designed to apply full-surface, pattern-free coatings using a roller-based system. They are commonly used in the production of architectural glass panels, as well as in specialized applications such as PCB printing and photoresist coating for LCD manufacturing. The coating process is continuous and uniform, ensuring consistent quality even on large-size substrates.

Single-roller coating machines are designed to apply even layers of paint or functional coatings across the entire surface of glass panels. They use a combination of a textured rubber roller and a transmission roller to achieve consistent full-width coverage without relying on screen plates. By eliminating the need for screen alignment or repositioning, these machines reduce setup time and streamline production.

Learn MoreDouble-roller coating machines are designed for the even application of coatings or paints on glass panels used in architectural, decorative, and home appliance applications. The setup features two rollers: a printing roller and an ink-homogenizing roller, each with independently adjustable rotation speeds for better control and uniformity.

Learn MoreGlass roller coaters are suitable for applying full-width coatings without patterns. Typical applications include architectural glass panels, printed circuit boards (PCBs), and LCD panels that require precise layers of photoresist ink.

Our roller coating machines ensure a smooth and even coating over the entire surface, minimizing common issues like dripping or inconsistent thickness. The result is a more uniform finish that improves both the visual quality and performance of the coated glass.

Coating width varies by model. Standard roller coating machines for glass are available in configurations with maximum widths of 1200 mm, 1800 mm, and 2400 mm.

There are single-roller and double-roller options. Single-roller machines use one set of rollers for coating application, while double-roller machines are equipped with two sets and are better suited for large, flat surfaces that require higher efficiency and full-area coverage.

Roller coaters operate at higher speeds, provide better efficiency, and eliminate the need for edge trimming. They produce an opaque and consistent finish, ideal for single-color coatings. However, they are not designed for multicolor or decorative printing, which is better handled by screen printing machines.

Contact us for more information about screen printing, drying, and handling systems for glass production. Our team is ready to assist you!